In today's demanding automotive industry, efficiency and precision are paramount. To meet these challenges, manufacturers have adopted automated tail light/lamp assembly systems. These sophisticated systems utilize a combination of robotics, sensors, and software to optimize the production process, resulting in reduced costs.

- Moreover, automated tail light/lamp assembly systems offer several perks over traditional manual methods.

- This technology lower the risk of human error, ensuring consistent and reliable production.

- Additionally, automation facilitates manufacturers to customize tail light/lamp designs to meet specific customer demands.

Ultimately, automated tail light/lamp assembly systems represent a significant advancement in the automotive manufacturing process, promoting efficiency, quality, and market competitiveness.

Advanced Forging Techniques for Tail Lamps

Modern automotive manufacturing demands increasingly efficient and innovative techniques to produce high-quality components. High-speed forging has emerged as a key process for creating complex tail lamp housings due to its ability to achieve exceptional strength, dimensional accuracy, and surface finish with minimal material waste. This article delves into the intricacies of high-speed forging/rapid forging/ultrasonic forging and its seamless integration with tail lamp manufacturing processes.

The stringent requirements of tail lamps necessitate precise design and robust fabrication methods. Ultrasonic forging offers a unique advantage by enabling the manufacture of complex shapes with intricate details, essential for accommodating advanced lighting systems. The process involves subjecting metal stock to high-velocity impacts under controlled conditions, resulting in a strong and consistent final product.

The integration of rapid forging with tail lamp manufacturing offers several benefits. It significantly reduces assembly steps, leading to increased productivity. Additionally, the process minimizes scrap generation, contributing to a more sustainable manufacturing approach.

Intelligent Tail Light Manufacturing: A Robotic Approach

The automotive industry is perpetually evolving, with manufacturers aiming to optimize vehicle safety and efficiency. One area of significant advancement is tail light manufacturing, where robotic automation shows to be a transformative force. By implementing sophisticated robots, manufacturers can produce tail lights with unprecedented accuracy, speed, and consistency.

- Additionally, robotic systems permit the integration of advanced features into tail lights, such as adaptive lighting technologies that alter brightness and form based on environmental conditions. This leads in enhanced visibility for drivers and pedestrians alike, adding to overall road safety.

- Additionally, the use of robots in tail light manufacturing decreases the risk of human error and optimizes production processes. This translates in lower costs, increased efficiency, and a improved output of high-quality tail lights.

With conclusion, intelligent tail light manufacturing with robotic assistance is revolutionizing the automotive industry. By utilizing this cutting-edge technology, manufacturers can create safer, more efficient, and sophisticated vehicles that meet the ever-evolving demands of the market.

Streamlining Tail Lamp Production with Automation boosting

hereThe automotive industry is continually seeking ways to enhance production efficiency while maintaining high-quality standards. Tail lamp manufacturing presents a prime opportunity for automation implementation. By integrating robotic systems, computer-aided design (CAD), and advanced sensors, manufacturers can drastically streamline the production process. This results in reduced labor costs, increased output, and improved consistency in tail lamp production.

- Robotic arms can automate repetitive tasks such as assembling components with precision and speed.

- Precise sensors monitor the manufacturing process in real-time, ensuring that each tail lamp meets stringent quality specifications.

- CAD software enables designers to create virtual prototypes and simulate production processes, reducing the need for physical testing.

Streamlining tail lamp production through automation not only enhances the manufacturing process but also allows companies to be more agile in the market. By embracing these technological advancements, automotive manufacturers can stay ahead of the curve and deliver high-quality tail lamps that meet evolving consumer demands.

Precision Engineering for Automated Tail Light Assembly

Within the demanding realm of automotive manufacturing, precision engineering plays a crucial role in ensuring the robust operation of various components. Notably, automated tail light assembly depends on meticulous methods to guarantee the flawless integration of intricate parts and materials. By incorporating cutting-edge technologies and stringent quality control measures, precision engineering enables manufacturers to produce high-performance tail lights that meet the stringent safety and performance standards of the automotive industry.

Smart Factory Solutions for Tail Light/Lamp Fabrication

The automobile industry is increasingly utilizing smart factory solutions to boost efficiency and production. Tail light and lamp fabrication, a essential component of vehicle safety and design, is no difference. By integrating cutting-edge technologies such as automation, manufacturers can improve the production process, reducing costs and enhancing product quality.

- Smart factory solutions for tail light fabrication often involve the use of automated systems to perform tasks such as cutting, welding, and assembly.

- Sensors are carefully placed throughout the production line to gather real-time data on machine performance, material usage, and product quality.

- This data is then analyzed using software to pinpoint areas for improvement.

The outcome is a optimized production process that produces high-quality tail lights and lamps in a timely manner.

Mason Gamble Then & Now!

Mason Gamble Then & Now! Alisan Porter Then & Now!

Alisan Porter Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! Justine Bateman Then & Now!

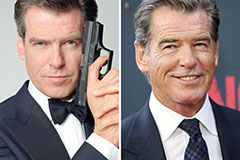

Justine Bateman Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!